Reduce Friction.

Improve Performance.

Coat components with Dicronite® dry film lubrication to prevent failure and increase efficiency .

The Original Tungsten Disulfide (WS2) Coating

The Original Tungsten Disulfide Coating

Solving some of the toughest friction related problems in high precision applications.

| Engineers trust the Dicronite® coating: | |

|---|---|

| to reduce energy lost to friction | in vacuum environments |

| to prevent galling and seizing | in extreme temperatures |

| to minimize excessive heat from friction | to improve mold release |

| as lubrication for tight tolerances | to lessen sliding wear |

| Engineers use dicronite® for: | |

|---|---|

| energy lost to friction | vacuum environment lubrication |

| galling and seizing | extreme temperature lubrication |

| mold release | lubrication for tight tolerances |

| sliding wear | excessive heat from friction |

THE DICRONITE® DIFFERENCE

For 60+ years, Dicronite® has been trusted to effectively lubricate:

- Actuators

- Ball Screws

- Bearings

- Bushings

- Chains

- Couplings

- Fasteners

- Gears

- Guides

- Molds

- Pins

- Shafts

- Sprockets

- Valves

- + More

- Actuators

- Ball Screws

- Bearings

- Bushings

- Chains

- Couplings

- Fasteners

- Gears

- Guides

- Molds

- Pins

- Shafts

- Sprockets

- Valves

- + More

USE CASES

Dicronite® can be applied to all metals, most plastics and some ceramics. The coating has been utilized across many sectors and high performance applications.

Dicronite® can be applied to all metals, most plastics and some ceramics. The coating has been utilized across many sectors and high performance applications.

COATING PROCESS

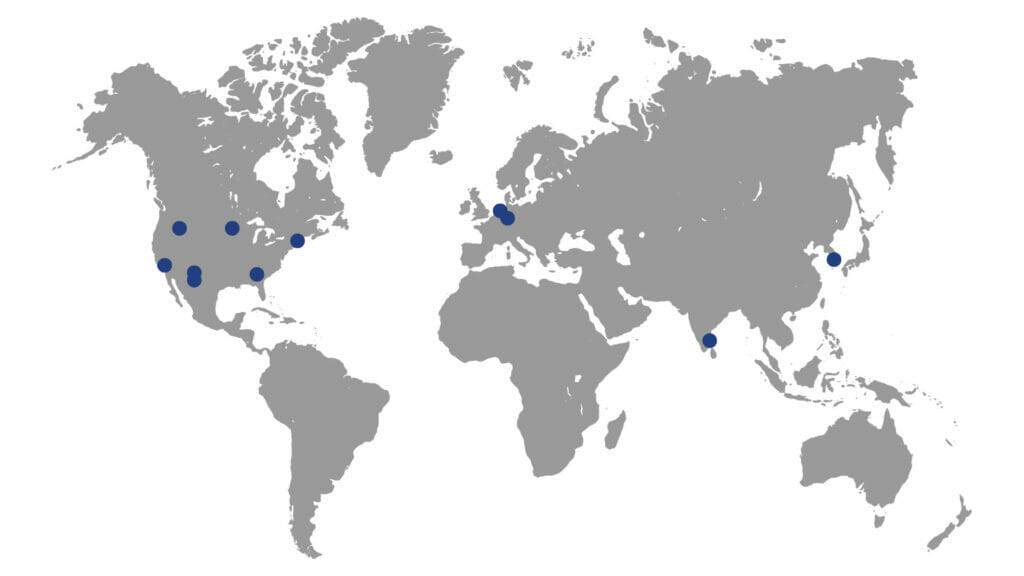

Dicronite® is a full, tungsten disulfide (WS2) coating service. With 11 worldwide locations, all you have to do is:

Dicronite® is a full, tungsten disulfide (WS2) coating service. With 11 worldwide locations, all you have to do is:

READY TO TALK TO AN EXPERT?

Join countless engineers who choose Dicronite® to improve component performance. Speak with an expert today.