Guided Projectile Actuators

Critical Need:

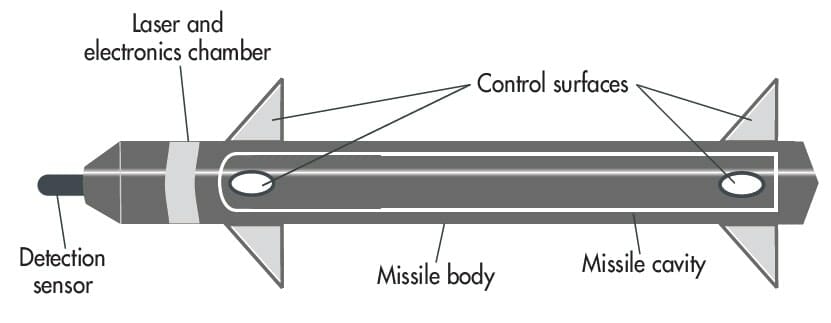

Control surfaces are a critical component of guided projectiles like missiles, smart bombs and decoys. They influence projectile range and maneuverability. Actuators adjust control surfaces, allowing for precise flight patterns and effective targeting of guided projectiles. The control surface actuators must be capable of outputting enough torque to overcome aerodynamic forces during projectile flight. If they cannot overcome these forces, projectile maneuverability suffers.

Requirements:

Control surface actuators must utilize a mechanical design that:

- meets torque output requirements,

- minimizes component weight,

- maintains the necessary load capacity, and

- has a 10-year shelf-life.

Design Solution:

Schatz Bearing Corporation provides bearings for projectile control surfaces that enable an optimized mechanical design. The system minimizes weight and breakaway torque while meeting load capacity requirements. Bearings are made of corrosion resistant steels which meet the 10-year shelf-life requirement.

Key to the design of these bearings is Dicronite® dry lubrication. By coating bearings with Dicronite®, Schatz effectively:

- reduces breakaway torque,

- increases mechanical efficiency,

- prevents micro-welding during storage, and

- prevents galling and fretting.

The Dicronite® coating handles the load capacity of its substrate (up to 350,000 psi), and has an indefinite shelf life when protected from substrate corrosion and physical damage. Ultimately, militaries whose missiles, smart bombs, and decoys contain Dicronite® coated Schatz bearings are able to effectively manipulate their guided projectiles.

Dicronite® DL-5® provides the dry lubrication necessary to precisely control these critical military weapons.

Learn more about Dicronite® coated bearings at www.schatzbearing.com