Problems Caused by Friction

Friction can cause critical problems in mechanical systems. You could be dealing with some of these issues caused by friction:

- Inefficiency from power losses

- Elevated operating temperatures

- Excessive wear

- Galling and seizing

- Component failure

- Full system failure

- Extra Maintenance

- Costly downtime

How to Reduce Friction

To prevent failures and reduce inefficiencies caused by friction, we must consider the whole system.

Friction is a system effect, meaning multiple factors within a mechanical system determine the friction that’s present.

This can include factors such as:

- Material type

- Material pair

- Contact force

- Contact geometry

- Surface roughness

- Type of motion

- Lubrication

What is Dicronite®?

Dicronite® is a dry lubricant that is used in mechanical systems to reduce friction, improve performance, and prevent failures.

This thin film coating, made of tungsten disulfide, is incredibly lubricious and can withstand extreme high or low temperatures and vacuum environments. In addition, its 0.5 micron average max thickness allows its use on assemblies with extremely tight tolerances.

Engineers trust Dicronite® in their most critical applications, including space, aviation, and defense applications.

This coating creates a blueish gray film when applied, and can be used on all metals, most plastics, and some ceramics, as well as on top of other coatings.

How does Lubrication Reduce Friction?

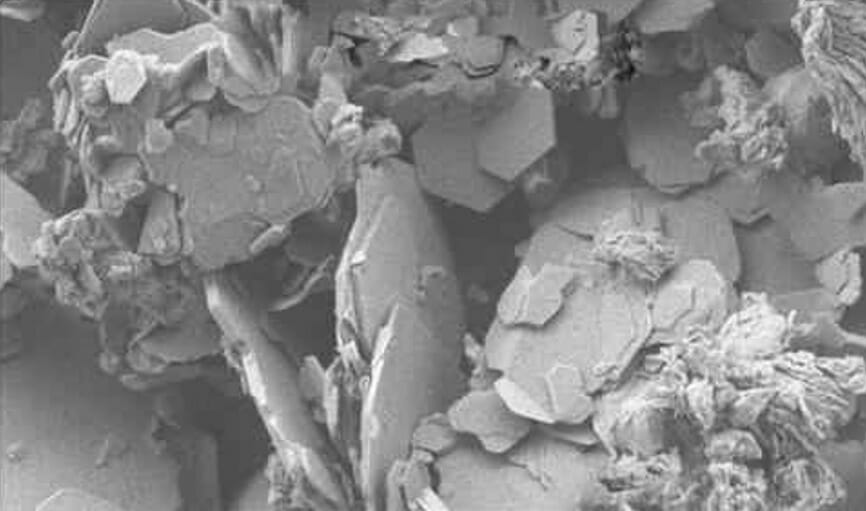

The molecular structure of Dicronite® forms stacks of thin layers, also referred to as a lamellar structure.

These thin layers are connected to each other by weak bonds that are easily broken. This allows layers to slide along one another with very low resistance, or low friction. With this in mind, optimal performance with Dicronite® is achieved when both contact surfaces are coated.

When Dicronite® is applied on contact surfaces, the material’s layers provide low friction sliding, effectively lubricating the surfaces.

Why use Dicronite® to reduce friction?

Originally developed for NASA, Dicronite® is valued for its extreme lubricity and ability to improve performance in various types of industries and applications.

It’s ability to reduce friction and prevent failure in extreme environments like high or low temperatures and vacuum make Dicronite® a critical solution to difficult friction problems.

Engineers have trusted Dicronite® to reduce friction on applications such as:

Why use Dicronite® to reduce friction?

Originally developed for NASA, Dicronite® is valued for its extreme lubricity and ability to improve performance in various types of industries and applications.

It’s ability to reduce friction and prevent failure in extreme environments like high or low temperatures and vacuum make Dicronite® a critical solution to difficult friction problems.

Engineers have trusted Dicronite® to reduce friction on applications such as:

With Dicronite®, users can:

Prevent failures due to friction

Increase efficiency and improve mechanical performance

Reduce sliding wear, extending component life

Avoid costly downtime and repairs