HASCO Plastic Injection

Problem:

HASCO®, an international mold manufacturer, was charged with creating plastic injection molding equipment for the manufacture of pharmaceutical spray bottle screw caps. The system design required:

- High dimensional stability of finished apart: 0.05mm for threads, sealing edges, and snap-in edges

- Suitability for clean room production

- Cycle time less than 17 seconds

- Effective demolding – part has undercuts, angled ribs, and threads

Design:

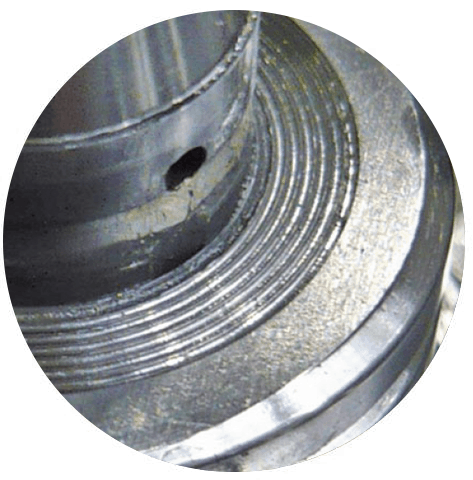

HASCO® engineers created an innovative solution and incorporated standard transmission components and prehardened, tempered stainless-steel molds. Dicronite® was applied on the molds and all transmission components including gear wheels, toothed racks, ball bearings, spherical bushings, guide rails, and guide blocks.

Results:

- Dimensional stability was maintained.

- Faster mold movements resulted in shorter cycle times.

- Friction and heat was reduced, resulting in less wear of transmission components.

- No additional lubrication was necessary and therefore, no particulates or outgassing compromised clean room environments.

- Dicronite® bonded to mold surfaces as well as guide rails treated with a hard coating.

Molds released effectively in extremely high temperatures.

With the help of Dicronite®, HASCO® delivered an effective clean room manufacturing solution capable of producing plastic parts for pharmaceutical use.