Dicronite® is the original

Tungsten Disulfide Coating

What is Dicronite®?

Dicronite® is a tungsten disulfide (WS2) solid lubricant coating. Tungsten disulfide occurs naturally as a rare mineral known as tungstenite, however it is typically synthesized using tungsten and sulfur.

While tungsten disulfide can be used in different fashions, the Dicronite® coating uses tungsten disulfide material specifically prepared for application as a dry film lubricant. This unique material preparation ensures optimal performance of the lubricant coating.

The Dicronite® coating is extremely thin, resists high and low temperatures, and functions in vacuum environments. Dicronite® meets the requirements of SAE specification AMS2530.

Dicronite® Coating

How does tungsten disulfide provide lubrication?

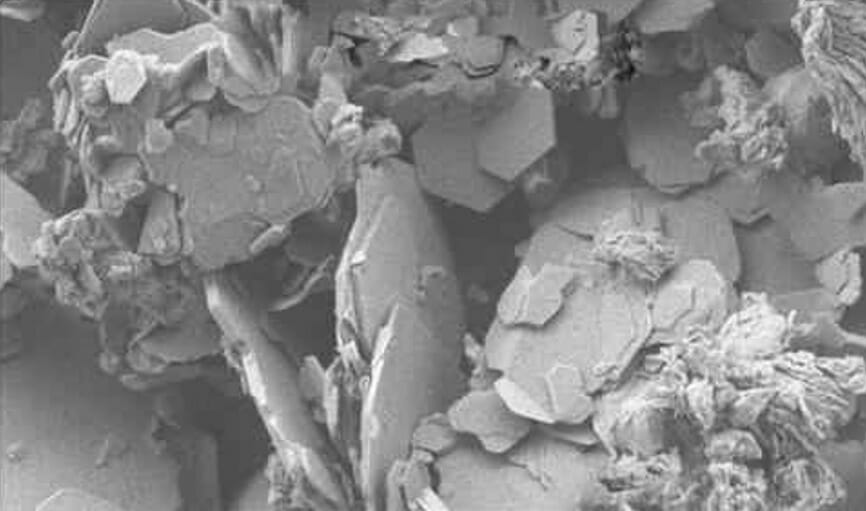

The molecular structure of tungsten disulfide (WS2) forms stacks of thin layers, also referred to as a lamellar structure. These thin layers are connected to each other by weak bonds that are easily broken.

This allows layers to slide along one another with very low resistance, or low friction. When Dicronite® is applied on contact surfaces, the material’s layers provide low friction sliding, effectively lubricating the surfaces.

Industries Served

Benefits of using the Dicronite® coating

Dicronite® is valued for its extreme lubricity and ability to improve component performance in various industries and applications.

It’s ability to reduce friction and makes Dicronite® a critical solution for countless engineers. With Dicronite®, users can:

- prevent failures due to friction

- increase efficiency and improve mechanical performance

- reduce sliding wear, extending component life

- avoid costly downtime and repairs

Tungsten disulfide coating properties

The Dicronite® coating is highly valued for it’s unique properties that allow it to be utilized in many high precision applications.

| Key Property | supporting Information |

|---|---|

| THICKNESS | Dicronite® has an average thickness of 0.5 microns (0.00002 inch) or less. The half micron thickness allows tolerances to remain unaffected, ensuring engineers can avoid redesign and easily incorporate the coating on existing designs. Due to the nature of the material, the coating won’t build up past the 0.5 micron avg limit, which means you never have to worry that the coating has been applied too thick. |

| TEMPERATURE STABILITY | Dicronite® is stable across a wide temperature range: up to approximately 538°C (1000°F) in air up to approximately 1316°C (2400°F) in vacuum down to approximately -188°C (-305°F) |

| VACUUM STABILITY | It’s very low outgassing makes it a great lubricant for applications dealing with vacuum conditions. Dicronite® is a spacecraft suitable material per ASTM E595. |

| COMPATIBILITY | Dicronite® can be applied on most substrates. This includes all metals, most plastics, and some ceramics. It may also be applied on top of other coatings or platings. Dicronite® is compatible with oils and greases and can be used in systems with fuels or hydraulic fluids. It’s also a non-toxic, biocompatible lubricant making it suitable for medical devices and applications within the food processing industry. |

| Engineers use dicronite® to help SOLVE friction related problems such as: | |

|---|---|

| energy lost to friction | vacuum environment lubrication |

| galling and seizing | extreme temperature lubrication |

| mold release | lubrication for tight tolerances |

| sliding wear | excessive heat from friction |

| fretting | |

| Engineers use dicronite® to help SOLVE friction related problems such as: | |

|---|---|

| tight tolerances | vacuum environment lubrication |

| galling and seizing | extreme temperature lubrication |

| mold release | excessive heat from friction |

| sliding wear | energy lost to friction |

| fretting | |

Common tungsten disulfide coating applications

Common components that are coated with Dicronite® include but are not limited to:

- Actuators

- Ball Screws

- Bearings

- Bushings

- Chains

- Couplings

- Fasteners

- Gears

- Guides

- Molds

- Pins

- Shafts

- Sprockets

- Valves

- + More

What does the Dicronite® coating look like?

Dicronite® typically takes on a dark gray or silver color, sometimes influenced by the color and finish of the underlying substrate.

Dicronite® can be applied to all metals, most plastics, and some ceramics. If you have questions about the coating on a specific substrate, ask an expert.

How is Dicronite® applied?

Tungsten disulfide (WS2) coatings can be applied by a few different methods; including aerosol, burnishing, tumbling, and impingement. While aerosol, burnishing, and tumbling applications may be viable in certain situations, most uses of WS2 coatings are best served by an impingement application process.

An impingement process, or high velocity spray process, is the standard for Dicronite® application. After surface preparation, Dicronite® dry lubricant is sprayed onto the substrate surface in ambient conditions. The coating material includes no binders or adhesives, and requires no curing. Dicronite® is commonly applied in accordance with SAE-AMS2530. This WS2 coating process is provided by any one of our worldwide application facilities.

See how the Dicronite® coating is used in your industry:

This tungsten disulfide (WS2) coating is highly valued by engineers throughout various industries. Typical industries include:

Additional Dicronite® tech data

-

CORROSION RESISTANCEProvides only minimal corrosion inhibition

-

CONDUCTIVITYWill not significantly affect surface conductivity (thermal or electrical)

-

CO-LUBRICATIONCompatible with oils and greases

-

LIQUIDS COMPATIBILITYCompatible with aviation fuels, hydraulic fluids, and many solvents

-

OXYGEN COMPATIBILITYSuitable for liquid and gaseous oxygen systems

-

RADIATION STABILITYStable (tested according to LEO and nuclear containment vessel radiation levels)

-

BIOCOMPATIBILITYBiocompatible per USP Class VI and ISO-10993 testing

-

LOAD CAPACITYSame as substrate, up to approximately 350,000 psi (2,415 MPa)

-

CHEMICAL STABILITYInert

-

TOXICITYNon-toxic

-

HARDNESS1.0 – 1.5 on Mohs’ scale

-

MAGNETISMNon-magnetic

-

HANDLINGSensitive to scratching and abrasion; prevent damage to coated surfaces

-

SUBSTRATE DEFORMATIONWill not induce stress to substrate

Quick & helpful documents

Click to view and print the PDF

The original tungsten disulfide coating service.

Dicronite® is applied at one of many worldwide licensed coating facilities.

After surface preparation, Dicronite® is impinged onto the surface at high velocity.

The material includes no binders or adhesives and requires no curing.

All you have to do is:

- Tell us about your application

- Send components to one of our application facilities

- Receive your expertly coated parts with little lead time.

DOMESTIC LOCATIONS

Southern California

Texas

Minnesota

Georgia

Massachusetts

INTERNATIONAL LOCATIONS

Mexico

The Netherlands

Germany

India

South Korea

Dicronite® has various application facilities that can provide the following quality certifications:

NADCAP

ITAR

ISO9001

AS9100

Submit an official quote today.

Join countless engineers who use Dicronite® to improve performance.

Additional questions? Our experts are here to help.