Biomedical Wire Connections

Situation:

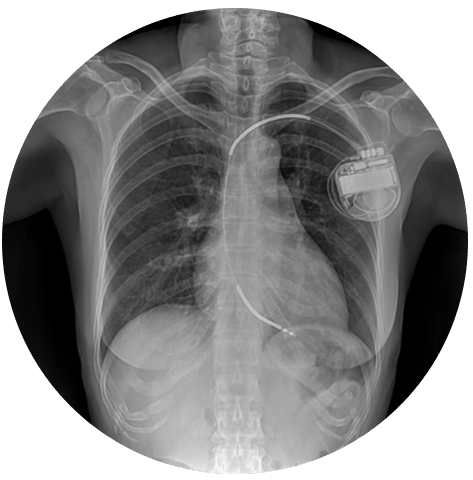

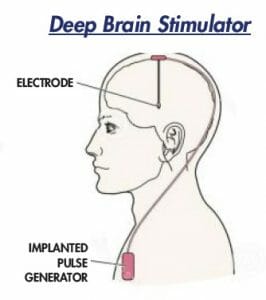

Medically implanted electrical devices improve and often extend lives. Engineers at Alfred E Mann Foundation for Scientic Research created a method of connecting biomedical wires that does not activate the body's natural defense system. The wires attach to implanted devices like sensors and stimulators. The method requires a sliding mechanism of two stainless steel parts. Since stainless steel is notorious for galling when rubbed against itself, the design requires a biocompatible lubricant.

Requirements:

In order to achieve their objectives, design engineers require a lubricant for wire connectors and crimpers that would:

- Not compromise the tolerances within a 1 mm electrode

- Allow for precision control of sliding components

- Adhere to materials used

- Prevent galling

- Provide long-term compatibility with the host such that tissue inamation, cellular alteration, and other adverse reactions are avoided or minimized

- Not be susceptible to damage or deterioration due to chemicals, electrolytes, or other substances present in the human body

Results:

Because Dicronite® is biocompatible and meets the design requirements, it was selected as the lubricant for wire connectors. Dicronite® bonded to the substrate and formed a strong, thin film. Testing confirmed that Dicronite® resisted hydrolysis, tolerated exposure to high temperatures and remained stable during autoclaving. This method for connecting wires compatible with human implants was successfully patented by Alfred E Mann Foundation for Scientific Research.