Chain Wear Reduction

Situation:

A major roller chain manufacturer wanted to reduce chain wear and extend maintenance intervals. They aimed to minimize costly down time caused by the need to frequently re-lubricate equipment.

Testing:

A set of control chains was lubricated with heavyduty wet lubricant (HD-4); a second set was

prepared with Dicronite® dry lubrication and the heavy-duty wet lubricant (Dicronite + HD-4).

The chains were then tested at ambient temperature, a speed of 798 feet per minute and

under an applied load of 533 pounds per strand of chain. Chain elongation measurements were taken at 50 pounds per square inch gauge pressure.

Results:

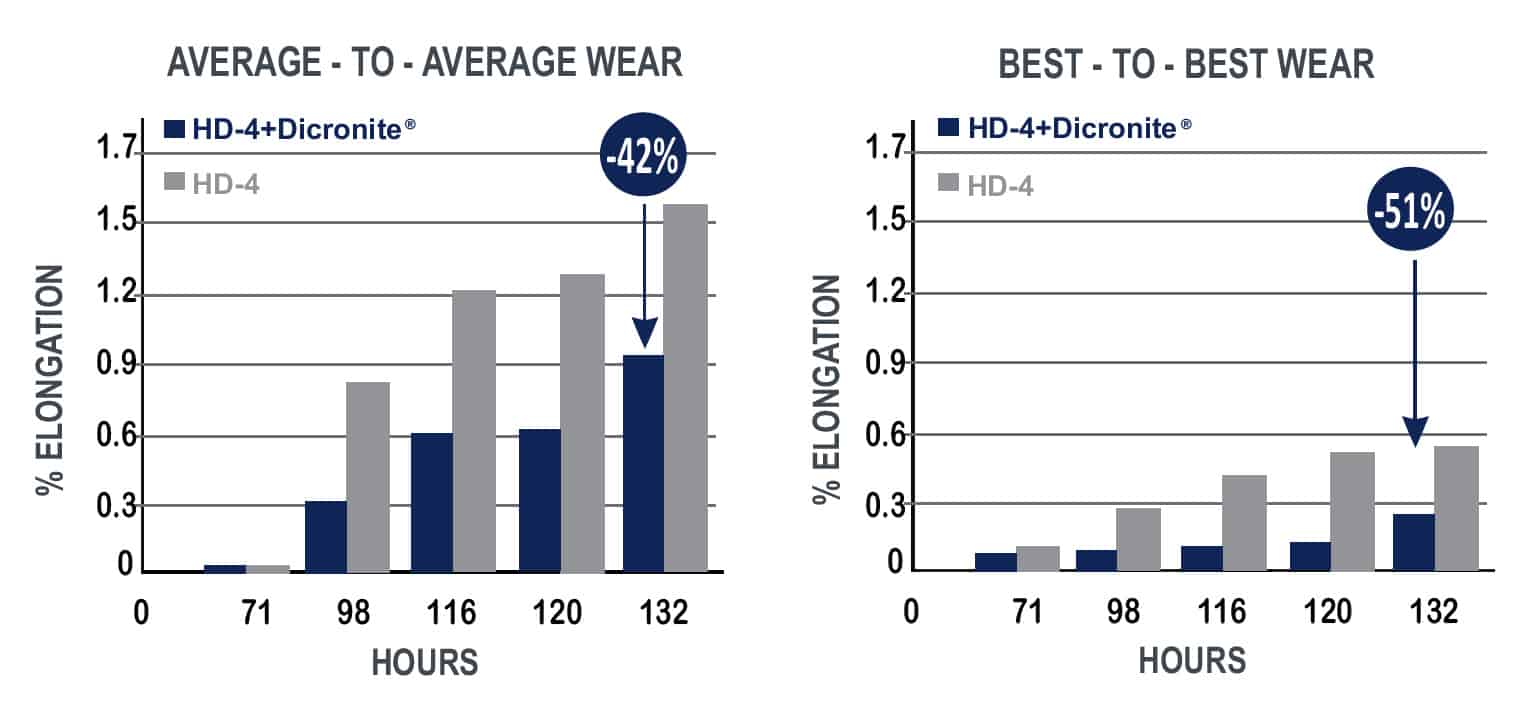

Testing was stopped at 132 hours (versus a planned 150 hours) due to one of the control chains breaking for a second time. Two parameters were measured at the 132-hour mark: the number of dry joints and chain elongation.

On average, the chains with Dicronite® had 42% less elongation than the control group. When comparing the best performing chain from each type, the Dicronite® coated chains displayed 51% less elongation. Notably, the Dicronite® chains averaged 42% fewer dry joints and 90%

less chain wear in the best case.

Adding Dicronite dry lubrication resulted in longer chain life, lower operating temperatures, less down time and extended maintenance intervals.